Login Into Your Account

Reset Password

Law enforcement Technology,Law enforcement Agency,Policing Technology,Smart Policing India,Homeland Security India,Border Security India,Border Management India,Cyber Crime news,Cyber Security news,Safety App,Public Safety App,Security App,Women Safety App,Police Initiative,Surveillance news,National Security news,isc event 2016,isc event 2017,scada event 2016,scada event 2017,Critical infrastructure security event 2016,Critical infrastructure security event 2017,iot summit 2016,iot summit 2017,Internet of things seminar 2016,Internet of things seminar 2017,iot seminar delhi 2016,iot seminar delhi 2017,iot conference delhi 2016,iot conference delhi 2017,top security event,security event,security event 2016,security event 2017,security conference 2016,security conference 2017,cso summit 2016,cso summit 2017,Corporate security event,Corporate security conference,security research india,homeland security research india,security think tank india

Law enforcement Technology,Law enforcement Agency,Policing Technology,Smart Policing India,Homeland Security India,Border Security India,Border Management India,Cyber Crime news,Cyber Security news,Safety App,Public Safety App,Security App,Women Safety App,Police Initiative,Surveillance news,National Security news,isc event 2016,isc event 2017,scada event 2016,scada event 2017,Critical infrastructure security event 2016,Critical infrastructure security event 2017,iot summit 2016,iot summit 2017,Internet of things seminar 2016,Internet of things seminar 2017,iot seminar delhi 2016,iot seminar delhi 2017,iot conference delhi 2016,iot conference delhi 2017,top security event,security event,security event 2016,security event 2017,security conference 2016,security conference 2017,cso summit 2016,cso summit 2017,Corporate security event,Corporate security conference,security research india,homeland security research india,security think tank india

Top 5 industrial internet of things use cases

Top 5 industrial IoT use cases

It’s important to note that IoT use cases will likely expand in the next few years. That being said, we have compiled the top five industrial IoT use cases of today:

Predictive maintenance

Keeping assets up and running has the potential to significantly decreasing operational expenditures (opex), and save companies millions of dollars. With the use of sensors, cameras and data analytics, managers in a range of industries are able to determine when a piece of equipment will fail before it ever does. These IoT-enabled systems can sense signs of warning, use data to create a maintenance timeline and preemptively service equipment before problems occur.

By leveraging streaming data from sensors and devices to quickly assess current conditions, recognize warning signs, deliver alerts and automatically trigger appropriate maintenance processes, IoT turns maintenance into a dynamic, rapid and automated task.

This approach promises cost savings over routine or time-based preventive maintenance, because tasks are performed only when they are needed. The key is to get the right information in the right time. This will allow managers to know which equipment needs maintenance, maintenance work can be better planned and systems remain online while workers stay on task. Other potential advantages include increased equipment lifetime, increased plant safety and fewer accidents with negative impact on environment.

Smart metering

A smart meter is an internet-capable device that measures energy, water or natural gas consumption of a building or home, according to Silicon Labs.

Traditional meters only measure total consumption, whereas smart meters record when and how much of a resource is consumed. Power companies are deploying smart meters to monitor consumer usage and adjust prices according to the time of day and season.

Smart metering benefits utilities by improving customer satisfaction with faster interaction, giving consumers more control of their energy usage to save money and reduce carbon emissions. Smart meters also give visibility of power consumption all the way to the meter so utilities can optimize energy distribution and take action to shift demand loads.

According to Sierra Wireless, smart metering helps utilities to:

Reduce operating expenses by managing manual operations remotely

Improve forecasting and streamline power-consumption

Improve customer service through profiling and segmentation

Reduce energy theft

Simplify micro-generation monitoring and track renewable power

Asset tracking

A study on the maturity of asset efficiency practices from Infosys and the Institute for Industrial Management (FIR) at Aachen University revealed that 85% of manufacturing companies globally are aware of asset efficiency, but only 15% of the surveyed firms have implemented it at a systematic level.

source: Actsoft

source: Actsoft

Infosys and other supporting companies including Bosch, GE, IBM, Intel, National Instruments and PTC have launched a testbed with the main goal of collecting asset information efficiently and accurately in real-time and running analytics to allow the firms to make the best decisions.

The goal of asset tracking is to allow an enterprise to easily locate and monitor key assets (e.g. raw materials, final products, and containers) and to optimize logistics, maintain inventory levels, prevent quality issues and detect theft.

One industry that heavily relies on asset tracking is maritime shipping. On a large scale, sensors help track the location of a ship at sea, and on a smaller scale they are able to provide the status and temperature of individual cargo containers. One benefit is real-time metrics on refrigerated containers. These containers must be stored at constant temperatures so that perishable goods remain fresh.

Each refrigerated container needs to be equipped with temperature sensors, a processing unit and a mobile transmitter. When temperatures differ from the optimal mark, crew can be notified and begin

Automated vehicles

Automated vehicles are all the rage now-a-days. In its simplest term, an automated vehicle is a computer-controlled car that drives itself. Current systems scan painted lines as one of several detection methods, future systems are envisioned that will be guided by magnetic rails and other forms of enhanced highways.

Source: The Daily Conversation/Youtube

Source: The Daily Conversation/Youtube

There are several advantages of driverless cars. Accident avoidance is a major incentive because the car can respond faster than a human. The ultimate manifestation is the overall reduction of vehicles, according to PCMag. Driverless taxis can replace a family’s second car that sits idle all day. More vehicles can travel closer on the road at the same time, and the computer can operate the vehicle more economically than most people.

Among the sensors feeding information into the differential GPS are cameras, radar, and lasers. Cameras let the car’s computers see what’s around it while Radar allows vehicles to see up to 100 meters away in the dark, rain, or snow. Lasers, which look like a spinning siren light, continuously scan the world around your car and provide the vehicle with a continuous, three-dimensional omni-directional view of its surroundings.

“These sensors are providing you with raw information of the world. You need very sophisticated algorithms to process all that information, just like a human would,” said Sridhar Lakshmanan, a self-driving auto expert and engineering professor at the University of Michigan-Dearborn, to Time.

Fleet management

Fleet management allows companies which rely on transportation in business to remove or minimize the risks associated with vehicle investment, improving efficiency, productivity and reducing their overall transportation and staff costs.

Asset tracking is becoming used more and more by cities for waste management purposes by giving trash collectors the most efficient routes to collect the buildup of trash in urban environments.

source: AT&T Enterprise/Youtube

source: AT&T Enterprise/Youtube

North America is expected to reach 12.7 million active fleet management systems deployed in commercial vehicle fleets in 2020, according to a recent study by Swedish M2M/IoT research firm Berg Insight.

The installed base of fleet management systems totaled 5.8 million at the end of 2015. The market is expected to grow at a compound annual growth rate (CAGR) of 17% during the 2015 to 2020 period.

The study also says that the number of active fleet management systems in Latin America is expected to increase from 2.3 million at the end of 2015 to 4.1 million in 2020.

The Cloud, the Edge, and the Industrial Internet

“Workers in the industrial sector have been under-served by computer productivity tools,” said John Magee, chief marketing officer at General Electric Co., a GE Digital subsidiary in an interview with the CUBE’s Jeff Frick (@JeffFrick) at GE Digital’s Innovation Day 2016. “We needed to develop a unique platform for industrial Internet of things solutions.”

GE’s Predix cloud platform, which was built in a new facility the company set up in the heart of Silicon Valley, is an effort to “work with customers on their own digital industrial transformation,” Magee said. Predix is a platform-as-a-service (platform) based upon Pivotal Software Inc.’s Cloud Foundry that is tuned to the unique requirements to industrial applications. Among those are the need to process many different types of data on different schedules and in different locations with goals ranging from improving efficiency to predicting failure to optimizing logistics. And that processing may have to be done under the harshest of environments, such as inside a jet engine at 35,000 feet or on a remote oil rig in the North Sea.

“Industrial companies have a set of unique requirements in terms of the types of data they work with, how they work with that data and the distributed nature of their plants and field assets,” Magee said.

For example, industrial machines often don’t have the luxury of high-speed Internet connections, or even any connection at all. “Industrial companies need to put computing right on a wind turbine or a jet engine,” Magee said. “They want to aggregate data in a manufacturing plant without having to send everything to the cloud.”

Optimized for the Edge: -

Predix achieves that through what GE calls an edge-to-cloud continuum. It’s essentially “an end-to-end cloud-based operating system that also supports edge nodes,” Magee said. “Wherever the Predix system is, whether it’s on the tiniest medical device or the largest locomotive, you’ve got the ability to run analytics at the edge and to benefit from the cloud.”

A core feature of the Predix platform is the “digital twin,” which is essentially a virtual representation of the physical assets the user is trying to optimize. This construct enables diagnoses and solutions to be matched to the unique situation and avoid the scenario in which “You and I drive our cars differently, but our manuals tell us to change the oil at the same time,” Magee said. “The digital twin gives us the ability to collect all that data, not by the manufactured spec, but by the performance requirements of a real-world environment,” he said. “You can optimize just for that asset.”

It also has the flexibility to support highly customized applications. For example, data streaming from a locomotive engine may be needed for on-the-spot analytics to diagnose potential equipment failures, but also stored in the cloud and for analysis in combination with data from other equipment.

Predix is also intended to offer flexibility at the back end for integration with legacy systems and equipment. “You’ve got all kinds of systems that have been there for many years, and companies now want to get data out of them to make more efficient operations,” Magee said. Predix uses the cloud as an interoperability layer to combine data from many sources and normalize it for analysis.

Standards will be crucial to the development of IoT. GE was one of the founding members of the Industrial Internet Consortium, which is racing to set standards based upon real world scenarios. One of the standards efforts is around interoperability.

Where to Begin?: -

How does an industrial company get started with Predix? There are myriad use cases, but most companies start with problems that have measurable payback, Magee said. “In medical equipment and transportation, for example, uptime is critical. Those kinds of investments are often a starting point,” he said. “Sometimes it’s in operational efficiencies like getting the right information to decision-makers who are doing maintenance.”

Whatever the scenario, IoT analytics promises to make computing power useful in whole new areas of the economy. Speed and variety will be characteristic of many of these new applications. “Analytics could be critical to an executive who’s making decisions about whether to expand their facilities or sell electricity on the spot market,” Magee said. “Or it could be as simple as helping an operator use a piece of equipment more effectively because of best practices discovered from data.”

Predix generated an estimated $6 billion in revenue for GE last year. With 50 million connected devices expected to come online over the next four years, the company has only scratched the surface of potential new value. “I think the sky is the limit,” Magee said.

What Everyone Should Know About The Internet Of Things

In order to help consumers understand, seven technology leaders from Forbes Technology Council explain what people should know about the IoT that they might not be aware of yet.

1. Devices Are Just Devices

Devices are simply devices. “The Cloud” is simply the internet. And data is always data. The IoT of things is nothing more than a new set of devices sending data to the internet, just like personal computers and mobile phones did before. If you think about it in this way, then many of the same rules of thumb and pitfalls apply. - Danny Boice,Trustify

2. Vendors Are Not Planning For The Obsolete

For example, Nest discontinued the API that powered Revolv smart-home products. The consequence was that all the devices people had bought immediately became unusable. As a consumer, you expect your fridge, TV or toaster to function for years before breaking. With IoT and the dependence on external APIs, consumers will increasingly find that their items stop working after 1-2 years. - Paulo Marques, Feedzai

3. The Concept Of Privacy By Design

The concept of privacy by design tackles the growing consumer concerns about privacy and the culture of corporate and government surveillance. Companies like Apple are combatting this by building privacy by design into their products. Techniques like ‘differential privacy’ allow companies to understand how their products are used by customers while protecting individual privacy. - Tim Barker, DataSift

4. They’re Easily Compromised

You must keep in mind that every connected device is a gateway into your home/environment. If you have a Nest thermostat, then there’s a chance (however small) that someone can hack into it and turn off your heat while you’re on vacation in the middle of winter, causing your pipes to burst. Millions of Android phones are already hacked and being used as part of DDoS attacks. The IoT could be next. - Sagi Brody, Webair

5. Devices Are Deeply Connected

I get the idea that people think that the IoT simply links devices together when, in fact, it creates its own personal network and becomes a much more powerful system. This system can do so much for the average consumer in terms of helping them make better decisions about utility use, securing their home, and adding convenience by taking over some tasks that then frees up their time. - Chalmers Brown, Due

6. Voice Control Will Make The IoT Easy To Embrace

The IoT conjures up images of smart, connected machines, but this picture is incomplete. Humans communicate using language, so we should expect voice to be integral to the IoT UX. Unlike generalist chatbots, a connected toaster or refrigerator has a specific context. That means we can expect simple, reliable voice interaction that will make our IoT future easy to embrace. - Matthew Russell, Digital Reasoning Systems Inc

7. Security Isn’t A One-Time Concern

Consumers tend to think about a device’s security during their initial purchase. But it must also be a focus as updates are made to ensure companies and user settings are providing consistent protection. The IoT enables technology to further embed in daily life and these devices will be around for a long time. It’s imperative that consumers think about longevity and the role security plays. - Neill Feather, SiteLock

How to solve the unique complexities of industrial IoT

The possibility of leveraging the data generated from billion-dollar machines communicating with one another creates tremendous potential for making our world more sustainable, efficient, and safe. The scale of the Industrial Internet of Things (IIoT) makes it uniquely complex – bigger problems with more expensive equipment require bigger solutions with more intricate, more connected technology.

In the industrial sector, IoT is often about bringing antiquated processes into the modern era so we can bring things like new foods, consumer products or services or alternative energy forms to market more quickly. Many of the manufacturing plants and oil refineries we work with today are running decades-old equipment.

This becomes less and less sustainable as the equipment gets older and the skilled laborers operating it age each year. Parts are harder to find, data from these systems become too hard to integrate into other systems and industrials can’t sustain the cost of running two separate systems and teams for OT and IT.

But IIoT is also about data and improving overall efficiencies in various processes, either to drive costs out or to increase production. This leads to more competitive companies driving new innovations faster. While the ROI from IIoT is still in its infancy, an example I can point to I saw recently involved a business partner using data and real-time analytics to monitor and optimize the performance of just one industrial kiln, which alone saved the company about $300K a year. That is an incredible example of the value of IIoT in action.

A more standardized infrastructure is needed:-

However, to realize more of these benefits, as an industry, we need a reliable and standardized infrastructure upon which to run these very IIoT components, since at its core IIoT is a journey where new solutions are integrated with old ones. This type of integration may be common in today’s data centers, but the same cannot be said as the infrastructure extends down through the factory floor.

The infrastructure of tomorrow needs to be virtualized, downtime-proof and easy to operate. Why? Beyond the physical requirements of the infrastructure, the technical skillsets of industrial operators need to evolve even further – in parallel with the rate of innovation of the equipment.

Beyond common standards, the other large barrier to advancing IIoT is security. Even if we had common standards — which we don’t today — until we as a sector figure out how to shut down or detect vulnerabilities in more connected systems, people will fear IIoT and all we can achieve with it, as the potential risks will push them too far out of their comfort zone.

Like cloud before IIoT, not everyone embraced innovation at the same rate. However, those who did invest in it early are now seeing the fruits of their labor on a larger scale than their peers who were slower to adopt. Similarly with IIoT, early innovators are working on trial projects, learning and adjusting as they see the potential for faster product development times, new business models and new ways to save money, while the slower adopters are still contemplating how much value IIoT can bring and how to get started.

Industrial IoT can enable a greater good: -

As we move forward as an industry, however, we also need to be conscious of the wake we create with this sort of disruption. One of the problems we’re potentially creating as an industry is the one we are actually trying to solve: by connecting devices we’re expanding our networks, but we’re also putting more eggs in one basket.

Think of a set of holiday lights – when one bulb is out, often the entire string goes out. In this hyper-connected, IIoT environment, more than ever, we need to think of the implications of an internet failure. The costs could be devastating to people, to businesses, to sectors like commerce and, in some markets, to entire economies.

These are concerns that are unsurprising when we consider how great of a transition we’re trying to drive for the industrial sector. A consumer may be concerned that his or her Nest may be feeding too much personal information to Google, but an operator of an oil rig needs to be concerned that he or she isn’t opening up an operation to hackers that could shut down a city’s access to oil.

These are concerns to pay close attention to, yes, but we must also recognize the greater good we’re enabling. This same oil operator stands to also create efficiencies that could drive down the price of gas and bolster local economies with a switch to IIoT and the more streamlined network of devices and technologies that go along with it.

It’s this scale and reach that make the Industrial Internet of Things a matter the population at large needs to be concerned with as opposed to just the everyday consumer – and it’s the job of the technology community to ensure IIoT’s growth and evolution is occurring at a pace that exposes us to its benefits more than to its vulnerabilities.

How industrial IoT is transforming public safety

A blend of industrial “internet of things; sensors and consumer devices are being used to enhance public safety and give critical visibility to law enforcement.

Here are some public safety use cases for internet of things innovations.

The cloud offers predictive policing: -

Predictive policing uses analytics and algorithms to identify potential areas or events of crime before they occur. Think “Minority Report.”

Companies like Predpol and Hitachi Data Systems offer tools designed to gather past type, place and time of crime to map criminal behavior patterns. This solution can then provide each law enforcement agency with customized crime predictions for the places and times crimes are most likely to occur.

Hitachi’s solution even uses data such as weather patterns, public transit movements, social media activity, gunshot sensors and several others to make its determination.

These innovations can improve law enforcement’s situational awareness, as well as provide the real-time information designed to help prevent incidents from becoming crises.

ShotSpotter: -

ShotSpotter is an already available product that uses sensors mounted in high crime areas to identify the sound of gunfire. The sensors identify the sound of a gun shot, determine its location, analyze the sound and send data to connected police stations within one minute.

ShotSpotter has been deployed in many cities around the country, and is said to be successful in lowering the rate of gun crime, according to Kova Corp. In Wilmington, North Carolina, for example, gun crime has been reduced by 2%, while homicides have decreased by 20% since installing ShotSpotter.

SecureCampus is one solution offered by ShotSpotter. According to the company, it is like a fire alarm in an active shooter situation: fire alarms don’t prevent fires but can offer a time advantage in the rare event a fire breaks out. That time advantage can mitigate the damage and save lives.

Analyses show the average active-shooter incident lasts 12 minutes and the first calls don’t come into 911 for a full three to five minutes. SecureCampus technology immediately alerts the police, and also provides police with real-time information such as an interior floor plan with how many and where the shots are fired.

ShotSpotter is a well known IoT solution. In fact, the City Council of Salinas, California, recently announced it would consider spending $1.5 million for ShotSpotter technology, according to KSBW8.

Cisco IPICS: -

Cisco IPICS is an emergency response interoperability system at Cisco offices across the United States, Europe and Asia Pacific. In scenarios like earthquakes, medical emergencies or a building evacuation triggered by a fire alarm, Cisco IPICS is designed to ensure rapid response from emergency teams as well as facilitates information flow to other relevant groups, such as human resources or the corporate crisis management team.

Cisco IPICS Dispatch Console is an end-to-end radio dispatching solution designed for mission-critical radio communications. The Dispatch Console client is the link between dispatchers and field personnel, helping coordinate field response and helping to ensure personnel safety. It extends existing push-to-talk radio channels or broadcast networks so users with a variety of communication devices, such as landline phones, cell phones, IP phones and satellite phones can share information and participate in an event.

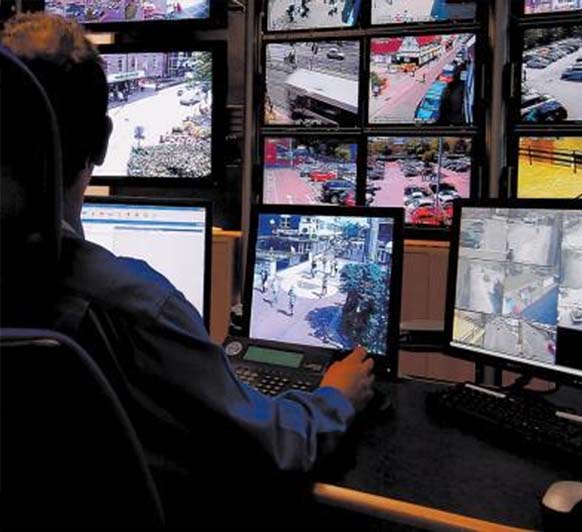

Video, drones and efficiency: -

Video quality and the resulting data and analysis from video feeds is more granular than ever. New, smarter algorithms for facial and license plate detection are helping law enforcement solve cases, and video feeds given to first responders allow them to accurately respond to a situation.

Drones are another important innovation designed to help law enforcement stay safe in high-danger situations by reaching areas that are difficult to reach or unsafe. In July 2016, police officers in Dallas used a drone to deploy a bomb near an active shooter, ending a situation that resulted in the death of five police officers.

The use of IoT can also give emergency crews quicker routes to a location by using highway sensors and adaptive traffic management.

Law enforcement: -

According to Cisco, integrating remote video and real-time collaboration at all levels of law enforcement allows agencies to:

1. Control evidence

2. Speed response time

3. Reduce crime

4. Control costs

With instant face-to-face collaboration, field personnel can reach experts and other resources without delay:

1. E-warrants: provide immediate access to courts from precinct or squad car.

2. Video arraignment: reduces costs and safety issues of detainee transport.

3. Remote appearance: eliminates travel and delays.

4. Remote interpretation: allows safety personnel to conduct field interviews without delays, no matter the language.

5. Situational awareness: delivers video and instant field status to and from the scene.

Emergency response: -

Here are the results of connecting emergency response crews, according to Cisco.

1. Comply with safety mandates and regulations.

2. Maintain constant contact with dispatchers and fleet managers.

3. Transmit live telematics data for proactive maintenance of vehicles.

4. Use a GPS device to guide them to the scene by way of the fastest and most direct route.

5. Use vehicle-to-infrastructure communication so vehicles can communicate with traffic lights, rail crossings, traffic cameras and roads. Also, high-resolution monitors can be loaded on emergency response vehicles to provide comprehensive intelligence and emergency management capabilities through multiple perspectives using video and sensor information. Images captured by first responders, and even drone-based video cameras, can provide real-time situational awareness back to commanders and headquarters, which can help incident commanders manage resources.

Is the Internet of Things putting your business at risk?

According to Palo Alto Networks, wireless network technology is simultaneously necessary and risky for organisations, and the Internet of Things could be putting businesses at risk of a cyber attack.

“Most businesses are aware that wireless connections can be risky so they look to mitigate the risks by protecting their internal infrastructure,” says Sean Duca, Vice President and Chief Security Officer, Asia Pacific of Palo Alto Networks.

“However, more and more new devices connecting to the internet are part of the Internet of Things (IoT), and may not necessarily come with built-in security measures that devices such as smartphones usually have,” he says.

“The automated nature of these devices and their communication means many businesses may not be aware of the security risks.”

IoT devices often transmit to and receive data from enterprise networks, creating possible vulnerabilities for organisations. As such, Duca says many cybercriminals are shifting their focus to finding vulnerabilities in mobile devices, networks, and applications to gain unauthorised entry into business networks, or unlawfully obtain sensitive information.

“Manufacturers of IoT devices are likely to use insecure and vulnerable firmware components, and the risk is exacerbated by the highly-connected and accessible nature of IoT devices,” Duca says,

“It is therefore essential to protect IoT devices against all possible threats.”

IoT devices may be connected to corporate networks to access and monitor other network equipment. Duca says this provides a perfect opening for malicious hackers to bypass security settings and, once on the inside, gain access to and control over other devices and, potentially, servers.

“To reduce the risks posed by IoT devices, organisations should use next-generation security technology to focus on network endpoints, such as mobile and portable devices, and the data flows within the network, rather than on simply protecting the internal IT infrastructure,” he explains.

“In addition, mobile network operators need to look beyond just telecommunication and network layer protection to technology that can also provide protection for the application layer and mobile services such as Skype.”

Brazil's M2M market to reach US$258.8bn in 2021

Novel applications and value-added services such as management platforms are expected to restore the average revenue per line (ARPL) in the Brazilian machine-to-machine (M2M) market. Revenue growth had slowed down during a period of intense competition and aggressive pricing, but the emergence of new applications requiring ubiquitous connectivity and higher value 3G/4G services are giving the market a much-needed stimulus.

Traditional applications will still dominate the M2M market in the medium term, but carriers are expanding their portfolios with more consumer-oriented applications such as connected cars, personal care and smart homes.

Such converged, verticalized solutions could well account for 35% of telcos' global revenues by 2018. Telcos are also looking at expanding into new verticals such as industry and agriculture, which have potential to generate higher ARPLs through advanced automation applications.

Telecom carriers are clearly aware that M2M holds much promise; as well as the market's top established players, all new entrants in Brazil's wireless market are focusing on this segment, the latter by leveraging the low-cost structure enabled by the mobile virtual network operator (MVNO) model.

"Telcos need to provide comprehensive solutions by integrating M2M into their B2B portfolio to capture the full value of M2M for clients," explained Frost & Sullivan Digital Transformation industry analyst Georgia Jordan.

"Additionally, carriers could enter into partnerships with key M2M vendors to offer and monetize end-to-end M2M solutions."

Meanwhile, regulatory initiatives are proving critical to driving M2M adoption in Brazil, particularly in industries such as energy and power. Although a law requiring all new cars to be shipped with embedded SIM cards was revoked in 2015, M2M service providers still have reasons to feel optimistic. They are awaiting the verdict on a proposal to substitute all electricity meters in the country with connected smart meters, which will greatly drive demand for M2M in the utilities segment.

The Brazilian M2M market currently enjoys governmental support in the form of tax exemptions, but these are limited to a few applications such as mobile-enabled point-of-sale (PoS) card payment terminals. Carriers are now lobbying to have them extended to all M2M connections, which will help widen the margins of the commoditized service.

So far, both enterprises and consumers have been cautious in their adoption of M2M technology due to unaddressed security issues. Security companies are working to plugging loopholes, but the specific tasks of M2M devices coupled with their dedicated security needs make it unfeasible for manufacturers to include additional security software.

"The cost issue is rapidly losing significance, as M2M applications are becoming increasingly affordable. This is encouraging the use of M2M modules in otherwise non-connected devices such as security cameras, alarms and health monitoring devices, as well as in tracking applications for pets and products in transit," observed Jordan. "It is also making mobile M2M the preferred backup technology or main connectivity solution for existing connected services such as ATMs, digital signage andsmart infrastructure."

General Electric and Cisco Dominate Industrial IoT Market

Research firm IDC talks about a growing interest in IoT: “U.S. organizations will invest more than $232 billion in Internet of Things hardware, software, services, and connectivity this year. And IDC expects U.S. IoT revenues will experience a compound annual growth rate of 16.1 percent over the 2015-2019 forecast period, reaching more than $357 billion in 2019.”

Now, we are facing the era when corporate giants all over the world compete to dominate the Internet of Things market. The main rivalry takes place between eight companies with market capitalizations over $150 billion – Google, Microsoft, Amazon, General Electric, AT&T, Verizon, IBM, and Cisco. It is interesting that only two of them – General Electric and Cisco – focus on industrial IoT.

Let’s study the approaches both companies take to prove themselves as trusted partners for IoT solutions.

General Electric: Focus on digital transformation: -

General Electric positions itself as the world’s premier digital industrial company that transforms the industry by connecting the physical and digital.

In 2014, the company developed an IoT platform based on the Cloud Foundry platform from Pivotal, a company that General Electric had previously invested $105 million in.

General Electric firmly counts on its roots in industrial business as well as on financial and technological investments in a modern cloud platform like Cloud Foundry. CEO Jeffrey Immelt says: “There is an incredible value around the asset in the industrial Internet that doesn’t exist in enterprise or the consumer Internet. In order for us to pull this off, we are going to have to create a horizontal company, a software analytics company, within GE.”

The company is known for its comment concerning digital transformation: “No matter where you enter the company, you are going to learn to code. Everybody. 100%.”

IDC enumerates manufacturing operations, transportation, and smart buildings as the most promising sectors for IoT. Although General Electric has the largest revenues in power, aviation, and healthcare, there are also billion dollar businesses in transportation, and appliances and lighting.

Cisco: Focus on connectivity: -

Cisco in its turn focuses on connectivity while delivering IoT solutions. It has already a customer database to be proud of:

BC Hydro, a Canadian utility company, employs Cisco Field Area Network and fog computing solutions to develop an IP-based, multi-service network to control smart meters, DA devices, and other grid endpoints.

The city of Mississauga, Canada’s sixth largest municipality, delivers city-wide Wi-Fi, connects its transit systems, modernizes buildings, and offers an intelligent streetlight system on the basis of the Cisco IoT System.

At the same time, the most significant move Cisco has taken to approach the leadership on IoT market is $1.4 billion acquisition of Jasper Technologies at the beginning of the year. The acquisition became the largest since 2013 when Cisco purchased cybersecurity company Sourcefire for about $2.5 billion. For the last years many smaller companies joined Cisco that sees investing in new products, such as data analytics software and cloud-based tools for data centers, rather profitable.

Cisco relies its IoT System on six technology pillars: Cisco Fog Computing, Network Connectivity, Physical and Cybersecurity, Data Analytics, Management and Automation, and Application Platform. The company though does not provide many details.

General Electric and Cisco Collaboration: -

Of course, two main candidates for industrial IoT leadership can’t avoid some kind of collaboration. Last year, they announced joint efforts to accelerate manufacturing productivity. It will be interesting to see how a network-centric approach from a company like Cisco will play out compared to an industrial equipment approach from General Electric.

Industrial Internet of Things Standards In the Works

Now, there is a need for a plant floor lingua franca—or at the very least, a way to standardize data sharing across production line machines.

Understanding that it requires collaboration to create an IIoT interoperability standard, three automation groups have joined forces to create a foundation for sharing IIoT information.

The Organization for Machine Automation and Control (OMAC), OPC Foundation, and PLCopen, which have worked independently on different aspects of automation standardization, are now combining efforts to create companion specifications for the standards and protocols they’ve already developed in order to allow seamless IIoT interoperability.

Here’s how:

1. One of OMAC’s major initiatives has been promotion of the ISA-TR88.00.02 automation standard commonly known as PackML. Manufacturers and machine builders worldwide have implemented ISA-TR88 on various control platforms to increase speed to production, ease packaging line integration and improve reliability. While PackML defines machine modes, states and tag naming conventions, it does not specify a communications protocol.

2. The OPC Foundation’s Unified Architecture (OPC UA) is an industrial interoperability framework. It delivers information modeling with integrated security, access rights, and all communication layers to provide plug and play machine-to-machine (M2M) communication inside factories. It is scalable across the plant floor and from sensor to IT enterprise and cloud scenarios. OPC and PLCopen—which is focused around IEC 61131-3, the only global standard for industrial control programming—worked together to define a set of function blocks to map the IEC 61131-3 standard for industrial controls programming to the OPC UA information communication model. The latest version was released earlier this year.

3. To take their efforts to the next level, OMAC and the OPC Foundation have established a global taskforce including individuals from each organization to develop a companion specification for ISA-TR88/PackML and OPC UA by the end of 2016.

4. Lastly, the collaborative efforts by these standards organizations will align with the Industrial Internet Consortium’s goal to ultimately identify and define building blocks for interoperability that make smart factories and IIoT possible.

“Standards are needed to support communications from machine-to-machine and from the plant floor to interfaces that will allow large scale data analytics and information transfer,” said John Kowal, a member of OMAC’s Board of Directors, co-chair of the Industrial Internet Consortium’s Smart Factory Task Group, and business development director for B&R Industrial Automation Corp. “It just makes sense for these organizations which have individually done so much to advance automated manufacturing to collaborate and avoid redundant developments.”

Industrial IoT and energy efficiency will slash carbon emissions

Over the next few decades, as the government’s “Made in India” initiative gains momentum, there shall be a greater reliance on industry to provide employment to millions. Many citizens of the country who are employed in rural regions are expected to be the workforce powering “Make in India”. Workers who currently work in rural sectors such as agriculture shall see an increase in their standard of living when employed as skilled or even unskilled workers in modern industries.

The demand for energy in the country is expected to double within 15 years. Due to the limited resources of fossil fuels in India, more efficient industries shall be needed to ensure abundant energy and harmonious economic growth. Such industries shall also ensure that fewer emissions are released into the atmosphere every year.

The impacts of so many factories: -

A caveat to any nation which relies on a large number of modern industries for economic growth is that such industries spew pollutants into the atmosphere. The expulsion of such pollutants is a given when a nation has within its borders even a large number of medium scale industries. Often industries can cause pollution in distant nations as well.

Much of the industry from the developed world relocated to poorer countries such as China because of lower wages in that country but also due to lower environmental safeguards in China. The lower environmental safety standards in China allowed developed countries to guard against environmental degradation at home. The movement of an immense number of industries to China led to many Chinese cities and parts of its countryside to become heavily polluted.

To prevent such large scale environmental problems in India as a result of greater industrial activity, more efficient industries shall be needed. Factories which leave a much smaller carbon footprint, are more efficient, and which make optimum use of resources shall be required if we are to increase the standard of living for millions while keeping the environment relatively free of pollutants.

As an industry becomes more efficient in utilizing its resources, lower amounts of emissions are released by it into the atmosphere. The use of sustainable energy is also crucial for a secure environment and economic progress.

How do we combat industrial pollution?: -

The Industrial Internet of Things (IIoT) promises greater efficiency for manufacturing facilities across the board. But this process data management colletion adn analysis is just the start.

There is today great potential to harness the wind to generate energy. Due to close proximity to the sea, wind potential in India to generate energy for millions is a viable option. The Shakti Sustainable Energy Foundation is one of the leaders in the country when it comes to promoting policies favorable to renewable energy. To make “Make in India” a success the leaders of the country must guard against pitfalls which often lead to erosion in the quality of air and water in the country. The citizens of China who live in many of its largest cities today pay a heavy price due to widespread pollution in their city’s air. Even the US is paying a price for relocating industries to China and not taking adequate safeguards against pollution as a jet stream over China carries pollution to the western part of the United States.

With widespread economic degradation across the planet today, there is a greater need than ever before for utilizing sustainable energy to promote greater wealth and a higher standard of living for the citizens of India. Sustainable energy derived from the sun and the wind is increasingly becoming viable and should be pursued to preserve the environment for future generations.

Newsletter

Sign Up for Monthly Newsletter

Recent Tweets

CONTACT US

Crux Center for Security

Research and Events (CCSRE)

3rd Floor, Tower-B, Unitech Cyber Park

Sector 39, Gurugram,122022

0124- 4207903, 05, 06

Copyright © 2016 Crux Center For Security Research And Events (CCSRE) | All Right Reserved